Premium Finishing. This is the ultimate in BLING surface finishing. Parts are brightened to a shiny, almost mirror like, finish by a 3 stage proprietary process. All B Vapor wetblast cabinets can achieve this finish with ease.

Satin finish. Clean and bright with a satin appearance. One step down in the brightness level compared to Premium Finishing. This finish is for customers who want a clean fresh satin finish with a more subtle outlook. Achieved with the use of correctly sized glass beads and pressure and flow settings.

When parts are to be painted after vapor blast cleaning, the surface needs a slight etch for the paint to bond to. Using either aluminium oxide, garnet or silicon carbide the surface profiling can easily be achieved. B Vapor blasting cabinets can create a wide range of surface roughnesses to suit the paint requirements.

Some components, particularly for restoration projects, do not require any adjustment to the part outlook. A shiny or etched surface is not required and the parts just need to be cleaned of years of build up corrosion and crud. B Vapor cabinet using sodium bicarbonate or plastic media will quickly and smoothly remove surface build up with no affect on the underlying surface.

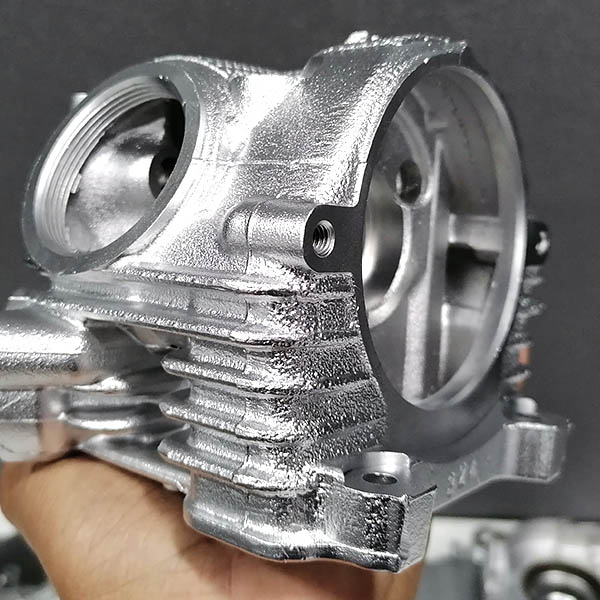

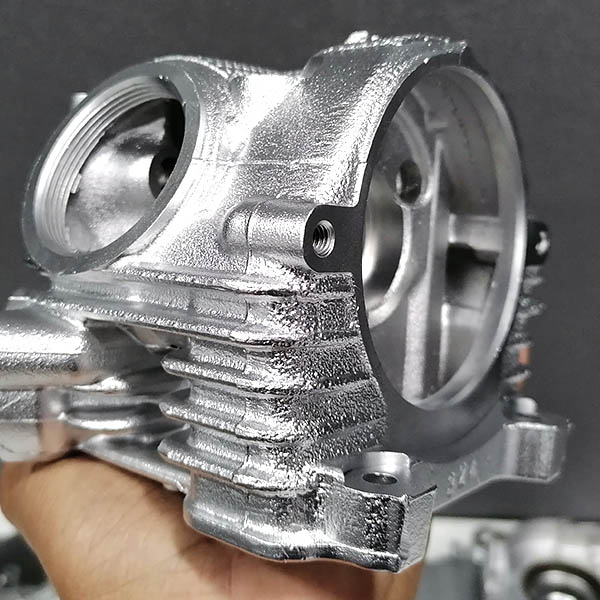

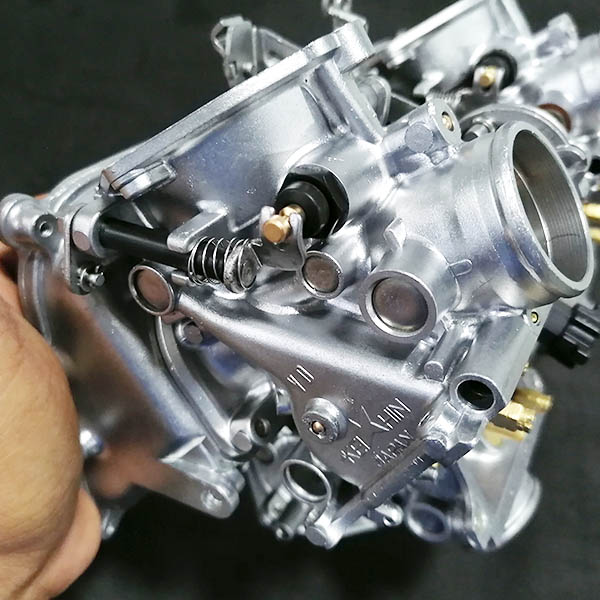

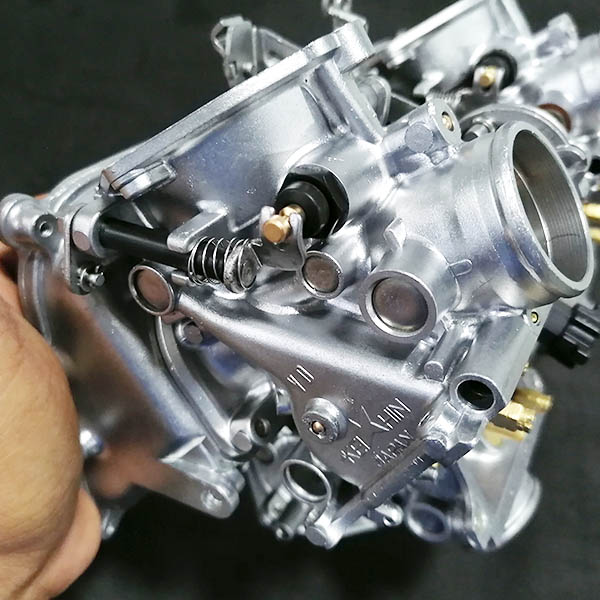

Refurbishing and repairs. Years of built up discolouration, crud and oxidisation can easily be removed from mechanical parts under going servicing and repairs. If parts require dismantling and inspection, vapor blasting will greatly assist in exposing the parts surface below the surface build up. Vapor blasting in a B Vapor cabinet will give old items a new lease of life, perfect for reuse or refurbished sale.

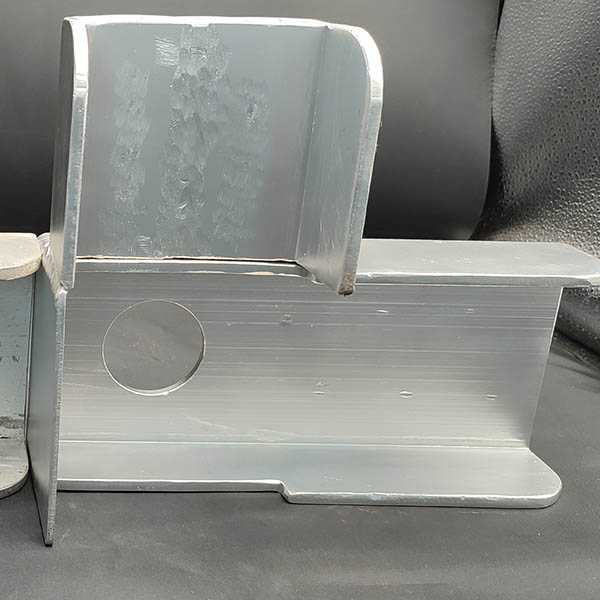

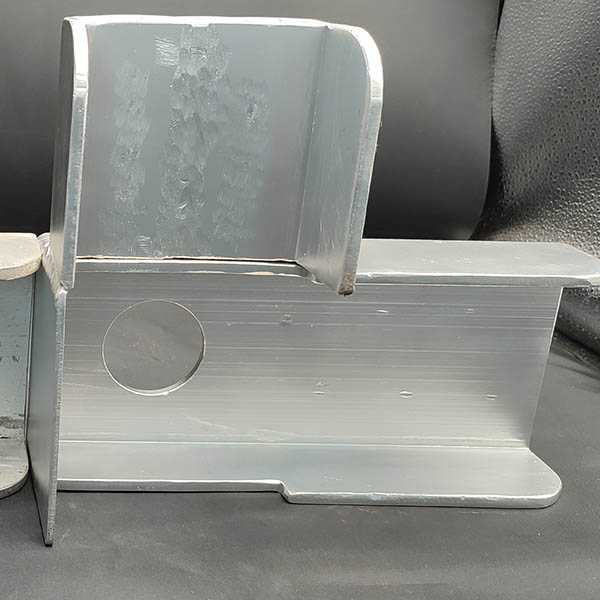

Heat stain removal. During fabrication of stainless steel parts, an unsightly heat stain can appear around the heat affected zone of the welding area. This is difficult to remove by hand and can leave the stainless steel looking rough and ugly. The fastest and most effective way to remove this staining is to process in a B Vapor blasting cabinet. The process using tiny glass beads will instantly remove even stubborn staining, and leave a smooth clean satin finish.

Over time uncoated aluminium forms a dull grey layer of oxidisation on its surface. The best way to remove this unsightly surface finish, and to provide a clean smooth satin finish, is through Vapor blasting in a B Vapor cabinet. As well as removing the oxidisation the vapour blasting process will also leave the surface clean and smooth and less susceptible to future oxidisation.